Choosing Stainless Steel Vs. Mild Steel

When it comes to metal fabrication, choosing the right type of steel is crucial for the success and longevity of your project. In this FAB402 article, we’ll talk about the two most commonly used types of steel in our industry: mild steel and stainless steel. We’ll define both types, explore their similarities and differences, weigh the pros and cons, and highlight the best applications for each.

In summary, choosing between mild steel and stainless steel depends on the specific requirements of your project. Mild steel offers affordability and ease of workability, making it a great choice for many small-scale fabrication projects. On the other hand, stainless steel provides superior corrosion resistance, strength, and aesthetic appeal, making it ideal for projects exposed to harsh environments or requiring a high-end finish.

For more information or to discuss your next project, please contact us today. We look forward to working with you!

What is Mild Steel?

Mild steel, also known as carbon steel, is a type of steel that contains a low percentage of carbon, typically around 0.05% to 0.25%. This low carbon content makes mild steel highly malleable and easy to work with.

Mild Steel Characteristics:

- Cost-Effective: Mild steel is generally more affordable compared to other types of steel, making it an economical choice for many applications.

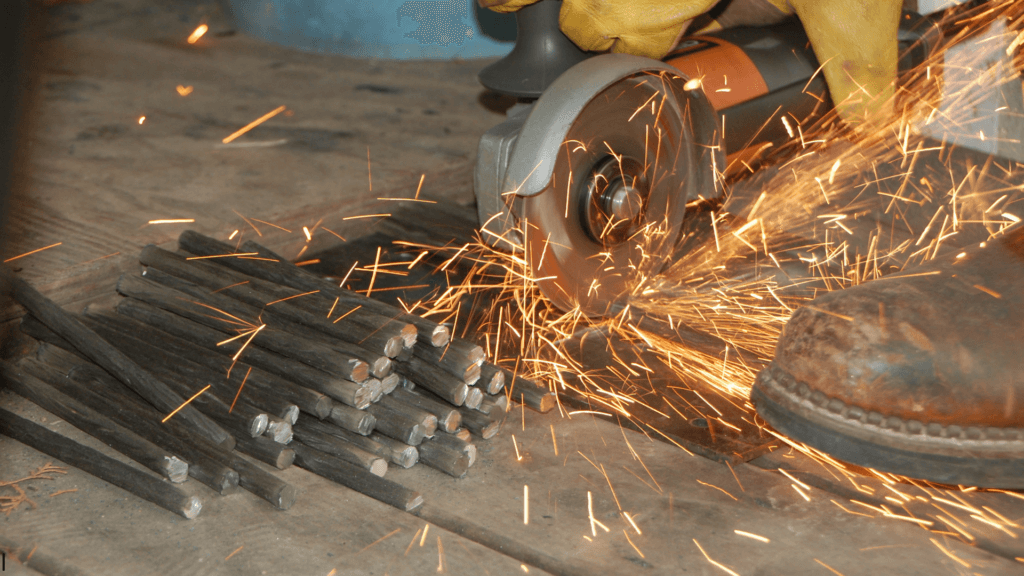

- Weldability: Due to its low carbon content, mild steel is easy to weld, making it a preferred material for projects requiring strong, consistent joints.

- Ductility: Mild steel is highly ductile, meaning it can be easily shaped, bent, and twisted without breaking.

- Magnetism: Mild steel is magnetic, which can be a factor to consider depending on your project’s requirements.

What is Stainless Steel?

Stainless steel is an alloy of iron, chromium (at least 10.5%), and other elements such as nickel and molybdenum. The addition of chromium gives stainless steel its unique ability to resist corrosion, staining, and rust.

Stainless Steel Characteristics

- Corrosion Resistance: The presence of chromium forms a thin oxide layer on the surface of stainless steel, which prevents rust and corrosion.

- Strength and Durability: Stainless steel is known for its strength and resistance to wear and tear, making it suitable for high-stress environments.

- Aesthetic Appeal: With its shiny, polished appearance, stainless steel is often used in projects where aesthetics are important.

- Non-Magnetic: Most stainless steels are non-magnetic, although some types can exhibit slight magnetic properties.

What is Stainless Steel?

Stainless steel is an alloy of iron, chromium (at least 10.5%), and other elements such as nickel and molybdenum. The addition of chromium gives stainless steel its unique ability to resist corrosion, staining, and rust.

Stainless Steel Characteristics:

- Corrosion Resistance: The presence of chromium forms a thin oxide layer on the surface of stainless steel, which prevents rust and corrosion.

- Strength and Durability: Stainless steel is known for its strength and resistance to wear and tear, making it suitable for high-stress environments.

- Aesthetic Appeal: With its shiny, polished appearance, stainless steel is often used in projects where aesthetics are important.

- Non-Magnetic: Most stainless steels are non-magnetic, although some types can exhibit slight magnetic properties.

- Versatility: Both mild steel and stainless steel are highly versatile and can be used in a wide range of applications, from construction to decorative projects.

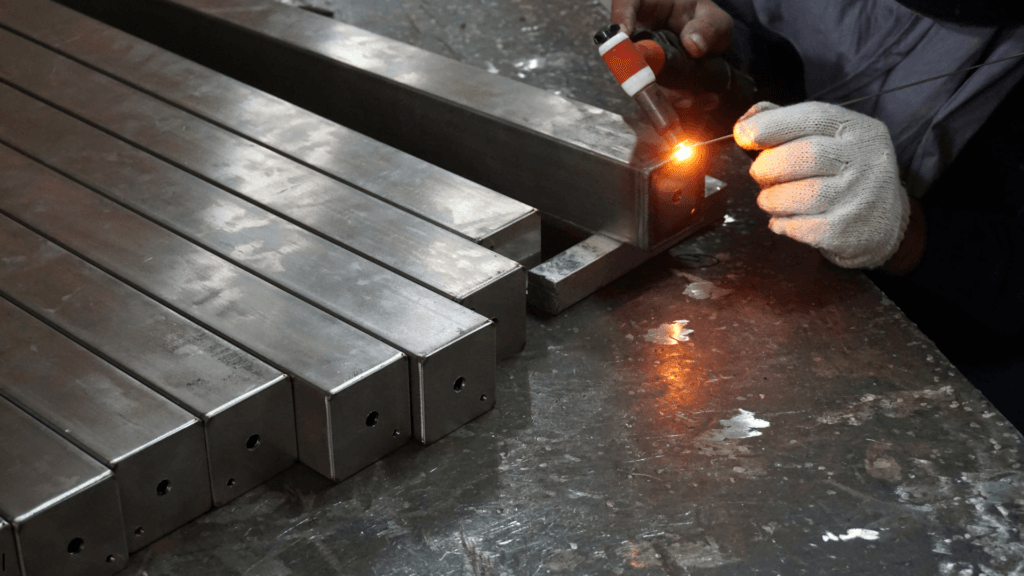

- Formability: Both types of steel are relatively easy to work with and can be cut, welded, and shaped into various forms.

- Strength: While stainless steel generally offers greater strength, both materials provide sufficient strength for many small-scale fabrication projects.

- Corrosion Resistance: Stainless steel has superior corrosion resistance compared to mild steel, making it ideal for outdoor and marine applications.

- Cost: Mild steel is more affordable than stainless steel, which can be a deciding factor for budget-conscious projects.

- Appearance: Stainless steel has a more polished, shiny appearance, whereas mild steel tends to have a duller finish.

- Magnetic Properties: Mild steel is magnetic, while stainless steel is typically non-magnetic.

Pros and Cons of Mild Steel

Pros:

- Cost-Effective: Lower cost makes it ideal for budget-friendly projects.

- Easy to Work With: High ductility and weldability simplify fabrication processes.

- Availability: Readily available in various forms and sizes.

Cons:

- Corrosion: Susceptible to rust and corrosion, especially in humid or salty environments.

- Maintenance: Requires regular maintenance and protective coatings to prevent rust.

Pros and Cons of Stainless Steel

Pros:

- Corrosion Resistance: Excellent resistance to rust and staining, suitable for harsh environments.

- Durability: Long-lasting and strong, with minimal maintenance required.

- Aesthetic Appeal: Shiny, polished appearance enhances visual appeal.

Cons:

- Cost: More expensive than mild steel.

- Workability: Harder to cut and shape, requiring specialized tools and techniques.