Metal Fabrication Trends For 2024

Advanced 3D Design Integration

In the fast-evolving world of metal fabrication, one trend stands out prominently – the integration of advanced 3D design technologies. This trend not only enhances the precision of our custom metal fabrication services but also allows clients to visualize their projects before they come to life. For those unfamiliar, 3D design provides a virtual model of the final product, ensuring accuracy and minimizing errors. This innovation not only caters to our seasoned clients but also makes the process more accessible for those new to metal fabrication.

Robotics in CNC Plasma Cutting

The utilization of robotics in CNC plasma cutting is reshaping the landscape of metal fabrication. This trend involves the incorporation of robotic systems in our CNC plasma cutting services, enhancing efficiency and speed. From intricate designs to bulk production, the precision offered by robotics ensures a high-quality output. For those less familiar with CNC plasma cutting, it’s a process where a computer-guided machine cuts through electrically conductive materials using a high-velocity jet of hot plasma. The addition of robotics takes this to the next level, ensuring consistent and accurate results.

Precision in Prototype Builds

Prototype builds are a crucial step in product development, and precision is key. The trend in 2024 is an increased focus on precision through advanced technologies. CNC machining and 3D printing are playing pivotal roles in ensuring that prototypes are not just prototypes but accurate representations of the final product. For those less versed in these technologies, it means a quicker and more reliable way to test and refine designs.

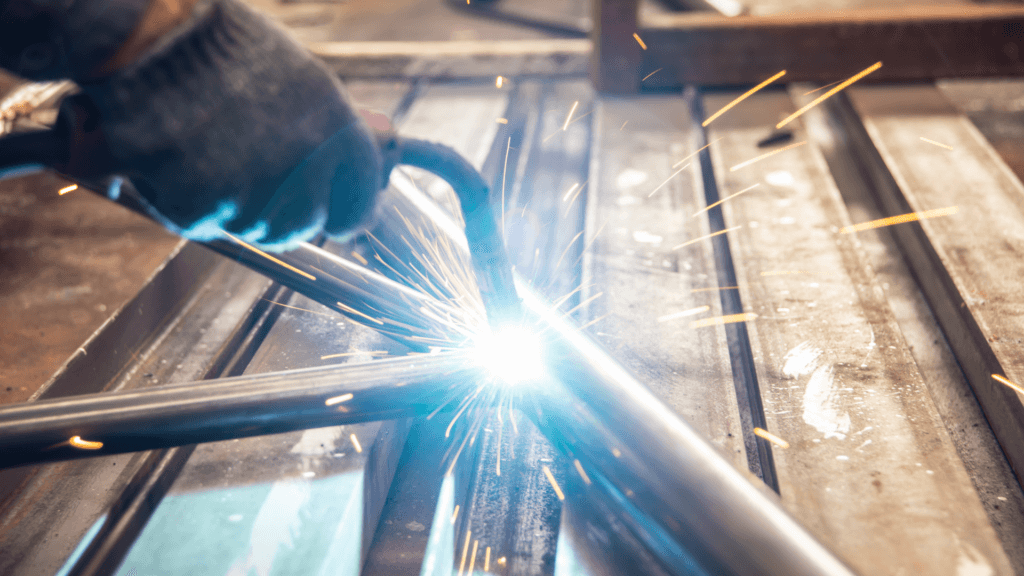

Innovative Welding Techniques

Welding services are at the core of metal fabrication, and in 2024, we’re witnessing a surge in innovative welding techniques. Techniques such as Friction Stir Welding and Laser Beam Welding, for example, are becoming more advanced and available. These innovative welding techniques, among others, showcase the industry’s commitment to advancing the quality, efficiency, and versatility of welding processes, ensuring that metal fabrication remains at the forefront of technological evolution.

Advanced materials and technologies are allowing for stronger and more durable welds, meeting the demands of complex projects. Whether you’re a DIY enthusiast or a welding professional, understanding the significance of these techniques ensures that the final product not only looks great but stands the test of time.

More Customization in Vehicle Modification

Vehicle modification is an art, and in 2024, customization takes center stage. From unique aesthetics to performance enhancements, our services in vehicle modification are witnessing a surge in personalized requests. This trend caters to both automotive enthusiasts and those looking for practical enhancements. Innovative trends and techniques allow for vehicles to be transformed to suit specific needs or preferences in new ways for 2024 and beyond, be it for utility or aesthetic appeal.

Focus on Remanufactured Parts

Remanufactured parts are gaining traction as a sustainable and cost-effective alternative. This trend involves restoring used parts to meet or exceed their original performance specifications. Whether you’re a DIY enthusiast or a professional, understanding the value of remanufactured parts ensures that your projects are not only cost-efficient but also contribute to a circular economy.

Artistic Integration in Custom Railings and Staircases

In the realm of residential metalworks, a notable trend is the artistic integration in custom railings and staircases. Homeowners are increasingly seeking unique and visually appealing designs that go beyond mere functionality. This trend involves blending artistic elements, such as intricate patterns or personalized motifs, into the fabrication of railings and staircases. For those looking to enhance their homes, it means turning functional structures into artistic focal points, adding a touch of individuality to the living space.

Collaboration and Knowledge Sharing

In the world of metal fabrication, collaboration and knowledge sharing are trends that never go out of style. The exchange of ideas, techniques, and expertise not only benefits professionals but also empowers clients. Whether you’re an industry veteran or someone exploring metal fabrication for the first time, the trend of collaboration ensures a collective growth and a better understanding of what this dynamic industry has to offer.

Diversity in Metal Material Usage

The trend of diversifying metal material usage is gaining momentum. Beyond traditional steel and aluminum, we’re witnessing a surge in the use of exotic alloys and composite materials. This trend caters to clients looking for specific properties such as lightweight structures, increased strength, or resistance to extreme conditions. Whether you’re a hobbyist or a professional, understanding the diverse range of materials available ensures that your projects meet the desired specifications.

Sustainability in Metalworks

As environmental consciousness continues to grow, the metal fabrication industry is embracing sustainability. From the materials used in custom metal fabrication to the disposal of waste, our commitment to eco-friendly practices is a notable trend this year. Sustainable metalworks involve utilizing recycled materials, minimizing energy consumption, and adopting processes that reduce the overall environmental impact. This not only aligns with global initiatives but also showcases dedication to responsible business practices.